Mixing performance is strongly influenced not only by impeller type and speed, but also by shaft orientation and entry

location. While top-mounted agitators are commonly used, many industrial processes—such as low and high-viscosity

mixing, crystallization, and solid-handling operations—often require inclined or bottom-entering shaft configurations

due to process, mechanical, or space constraints.

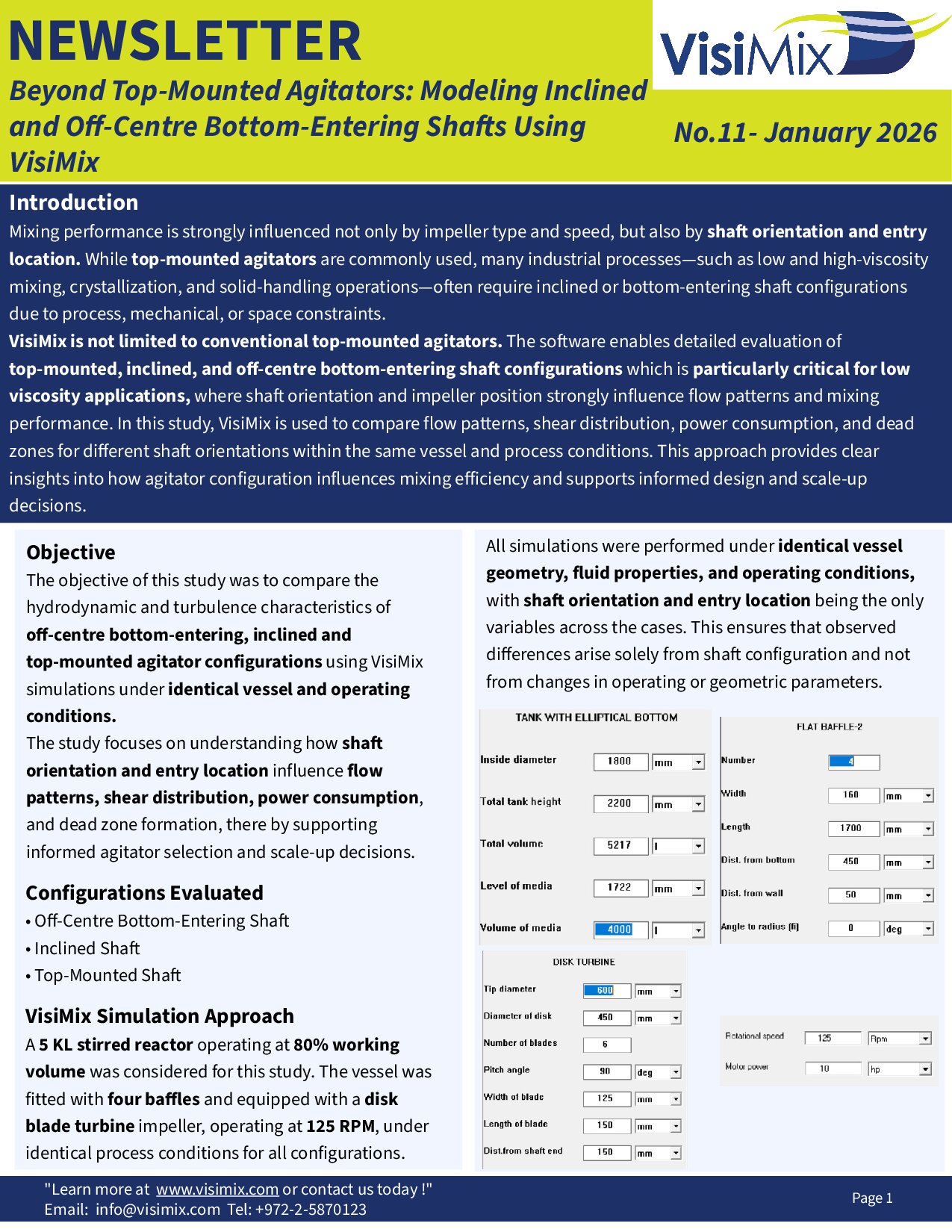

VisiMix is not limited to conventional top-mounted agitators. The software enables detailed evaluation of

top-mounted, inclined, and off-centre bottom-entering shaft configurations which is particularly critical for low

viscosity applications, where shaft orientation and impeller position strongly influence flow patterns and mixing

performance. In this study, VisiMix is used to compare flow patterns, shear distribution, power consumption, and dead

zones for different shaft orientations within the same vessel and process conditions. This approach provides clear

insights into how agitator configuration influences mixing efficiency and supports informed design and scale-up

decisions.